Page 1 / 8

Design &

Construction |

|

|

06/04/2012

Most of the arcade games I play, are vertical

games. Mr. Do!, Donkey Kong and Galaga are are some of my

favourite games. They are all with vertical screen orientation

and they all need only on set of controls with just one button. So naturally I wan't

to make a cabinet just perfect for this type of old school

arcade games.

I would like to thank ArcadeShop.de for sponsoring some of the parts for this

project. I can definitely recommend Arcadeshop.de for their great

support and great products. Now go buy some pushbuttons and

joysticks, you will not find a better place to do so:

--->

<---

<---

|

|

|

My goal was to make a compact cabinet with a

vertical mounted 17" LCD monitor. This way you could also use

the design for a regular mounted 19" monitor by making the

cabinet a few inches wider. This way more people will hopefully

benefit from the design files I will make available soon :)

The cabinet basically started out like the

sketch on the left

and ended up looking like the one to the right. I made about 15

sketches in between ending up with the result on the right due

to size limitations and restrictions internally.

I don't think I could have made a more compact

design to fit a vertical 17" or a horizontal 19". Most of my

design are based around the idea of making the most compact

cabinet possible. Less is more - in my opinion.

|

|

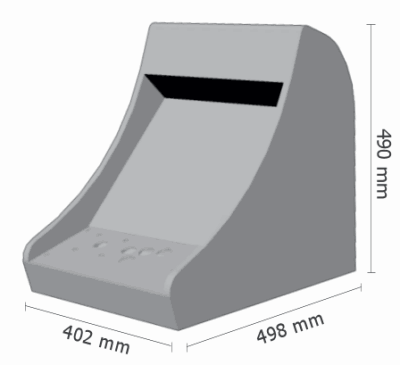

Here is a simple 3D model of the cabinet. I think it is a little

bit more modern, sleek and streamlined than the WeeCade design.

I can only hope it will be as popular.

IMO this design has some advantages because of the low height of

the control panel. I always found that the WeeCade was too high

to use comfortably at a normal table. |

|

The control panels is made of two layers of 5 mm

acrylics, but you could also use 12 mm MDF.

My design only has four pushbuttons, but the is easily room for

six buttons there. But I don't think there is any need of more

than four buttons for me.

Opposed to my other control panels, this has holes for bolts. I

don't have access to making the special brackets and metal

control panels I have used earlier on, but with four button head

Allen bolts, this should look fantastic too. The top layer has

larger holes for the bolt heads, so they are recessed in the

layer and will be flush with the surface.

I will make the control panel available for purchase through my

acrylic dealer later. I will make a version with six push

buttons too. |

|

The two layers of acrylics are merged with

a special solution for acrylics. Basically they become one

piece after just a few minutes.

I use tomato cans for this job, but you could also use pies,

pineapple, spam, beans or even beer cans...

The solution I'm using here is Evonik Acrifix 116. In the US

there are similar products from Weld-on and TENSOL in the UK.

|

|

Time to cut out the side panels from the 16 mm MDF board with a

jigsaw. You definitely become better at this by practising and

the key is to go slow and steady. Don't push forward, have

patience. |

|

After cutting out both sides, they were

processed with a milling machine to make the edges rounded. You

could also use T-moulding for a much stronger edges. I don't

have the tools to do T-moulding at the moment.

|

|

Now it's time to make the mouldings. I have made the mouldings

myself by cutting up some spare planks. I made them 22 mm by 22

mm. If you have a circular saw, this is a much cheaper way to do

it, and it can literally be done in minutes. |

|

When making the mouldings, a very easy way of saving some time

and getting the best possible end result, is to make both sides

simultaneously. This way you can make them look exactly the

same. |

|

Time for fastening the mouldings. You only need to use a few

screws, the glue should do the rest. Place the screws so that

you make room for the other screws when mounting the panels. |

|

Once again I try to do both sides simultaneously to ensure a

perfect mirrored result. |

|

|

Join

our Facebook group and receive updates and discuss MAME cabinets

with fellow retro gamers: Join

our Facebook group and receive updates and discuss MAME cabinets

with fellow retro gamers: |

|

Page 1 / 8 - Design &

Construction |

|

|

|

|

If you decide to make your own MAME cabinet using my drawings, please feel free to

make a donation, as I'm trying to raise enough money to make a new

up-right cabinet, that's hard to do as a student. |

|